Disassemble the central control screen of Tesla Model 3 to see what chips and electronic components are present

Global electronic component supplier AMPHEO PTY LTD: Rich inventory for one-stop shopping. Inquire easily, and receive fast, customized solutions and quotes.

Introduction: I recently had some time to sit down and sort out the materials carefully. Some time ago, a friend wanted to analyze the central control screen of Tesla Model 3. It is not easy to buy a competing product after disassembling it. I had some exchanges with friend a few days ago about the current hot spots of smart cockpits. This area is moving towards one machine with multiple screens, migrating from the traditional chip platforms of Renesas and NXP to the high computing power of Intel and Qualcomm. The separation of software and hardware was also first launched in this field.

1. Model 3’s central control screen

The disassembly information is derived from IHS benchmark, and part of it is disclosed on Electronics360. The main information is as follows:

- LG 15.4-inch IPS 1920x1200 monitor, weighs 828g, total manufacturing cost estimated at $198.84

- 15.4OGS direct bonded touch screen with cover glass

- Die-cast magnesium alloy housing

Figure 1. Central control screen disassembly outline Source: IHS Markit

The main components include, in fact, mainly two boards

Figure 2 The main part of the screen is mainly divided into two panels

- 15.4" Diagonal, TFT LCD, a-Si, IPS, 1920 x 1200, N/T, 828g - MFR: LG DISPLAY CO LTD - MPN: LA154WU1-SL01

- 15.4" Diagonal, OGS Type, Direct Bonding, w/ Tempered Cover Glass, w/ Integral Flex PCB

- Enclosure, Main, Rear Cover, Die-Cast Magnesium Alloy, Machined, Painted, Laser Etched

- Device Mount Housing, Injection Molded Plastic, Painted

- Device Mount Housing Door, Injection Molded Plastic, Painted

- Temperature Sensor Module Housing, Bottom, Injection Molded ABS Polycarbonate

- Protect Film, Clear Plastic Sheet, Die-Cut

- Temperature Sensor Module Housing, Top, Injection Molded ABS Polycarbonate

- Temperature Sensing Element, Formed Copper, Painted

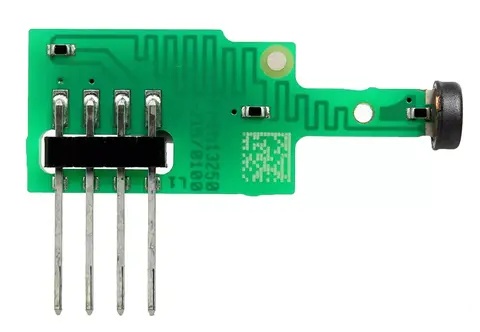

Figure 3 Temperature acquisition board Source: IHS Markit

- Fastener, Machine Screw, M5.8 x 12mm, Torx Pan Washer Head This motherboard is mainly divided into 7 chips

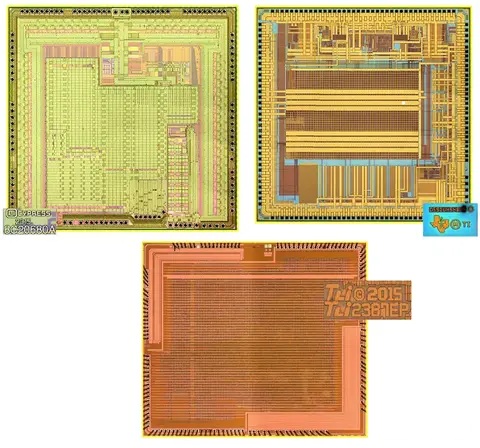

- CYPRESS (now in Infineon) CYAT81688-128AS88Z Touchscreen Controller, Capacitive, Multi-Touch, 32-Bit ARM Cortex CPU Cor

- TI DS90UB948TNKD, Deserializer, FDP-Link III to Open LDl.2 Lanes, 192MHz, Up to 2K Resolutions with 24-Bit Color Depth

- Tli INC, Tli2387EP_B, Display Timing Controller

- RENESAS ISL24858IRXZ Programmable Voltage Reference (10-Bit, 14-Channel, I2C Programmable, w/Integrated Buffered Outputs, Calibrator, Amplifier, EEPROM)

- TI (TMP758QDGK) Digital Temperature Sensor 12-Bit, 2-Wire Interface

- ROHM (BD9465MUV) Backlight LED Driver 4-Channel, 150mA per Channel

- ConnectorsMale, Vertical, Gold Plated Contacts, w/1 2-Pin Header

Figure 4 & 5 The screen's main control board and main control chip Source: IHS Markit

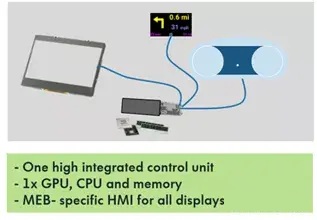

2. Comparison with MEB

We know that in the MEB project, Volkswagen chose to make improvements on the original MIB, and chose one controller for the three display sources (instrument, central control and HUD). The approach itself is similar, breaking the original hardware and software integrated design in the instrument, and also breaking the software inside the HUD, and combining the three into a centralized unit. Therefore, it is foreseeable that in the future, the HUD, instrument screen and central control screen will be hardware + simple software.

Figure 6 MEB ICAS3 design concept

In the end, this was indeed done. My understanding is that Volkswagen will integrate the three ICAS in the form of boards and cancel the Ethernet between the cards. It is designed completely in the form of industrial control hosts in the industry. The overall concentration of computing power and the simplification of external hardware will indeed reconstruct the existing parts system. This power of reconstruction can enable large-volume vehicle companies to seize the core power of bargaining with suppliers and take back the most valuable part.

Figure 7 ICAS physical appearance

Summary: In the past, car companies selected chip platforms more in the form of quality certification. In the future, selecting chip platforms will be a bit like selecting CPUs for desktops or iPads. The lower-level displays, actuators, and sensors will usher in further modularization and low-costization. These components will be completely low-cost, which will also promote car companies to move closer to screen and core chip manufacturing.