Testing IGBT: Methods for Evaluating IGBT Performance and Reliability

November 10 2023  1549

1549

Inquiry

Global electronic component supplier AMPHEO PTY LTD: Rich inventory for one-stop shopping. Inquire easily, and receive fast, customized solutions and quotes.

QUICK RFQ

ADD TO RFQ LIST

The Insulated Gate Bipolar Transistor (IGBT), a power semiconductor device, is a fundamental component of contemporary electronics. Its exceptional efficiency and controllability, together with its special ability to switch both high voltage and current, have catapulted it to the forefront of applications, from power inverters and motor drives to switching power supplies and induction heating systems. To guarantee their best performance and dependability, IGBTs must undergo extensive testing due to the demands made on them in various applications. In this blog, we will delve into the realm of IGBT testing, offering a comprehensive examination of approaches, strategies, and the importance of this vital procedure. This blog article will give you the information and understanding you need to test and maintain these crucial devices, whether you're an electronics enthusiast looking for a deeper understanding or a professional dealing with IGBTs.

What does IGBT stand for?

IGBT stands for Insulated Gate Bipolar Transistor. It is a kind of power semiconductor device that combines the benefits of bipolar junction transistors (BJTs) and metal-oxide-semiconductor field-effect transistors (MOSFETs). IGBTs are frequently found in devices like power supplies, motor drives, and inverters that need to flip between high voltage and high current.

Structure and Operation of an IGBT

An IGBT consists of four layers of semiconductor material arranged in a P-N-P-N configuration. This unique structure allows for control of the current flow between the collector and emitter terminals by applying a voltage to the gate terminal. The gate is insulated from the other terminals, enabling precise and efficient control.IGBT vs MOSFET

IGBTs and MOSFETs are both power semiconductor devices commonly used in electronic circuits. However, they differ in their structure, control mechanism, and performance characteristics.- Structure: The structure of MOSFETs is three layers, whereas that of IGBTs is four layers.

- Control Mechanism: MOSFETs primarily rely on voltage control, whereas IGBTs use a combination of voltage and current control.

- Performance Characteristics: Although they have somewhat slower switching speeds than MOSFETs, IGBTs can often handle larger voltages and currents.

What is the Advantage of IGBT?

IGBTs offer several advantages that make them a preferred choice in various applications:- High Voltage and Current Handling: IGBTs are appropriate for applications that require a lot of power since they can withstand high voltages and currents.

- Low Conduction Losses: IGBTs have little conduction losses, which enhances their efficiency.

- Robustness: IGBTs can tolerate challenging operating conditions and are comparatively robust.

Importance of Testing IGBTs

- Ensuring device reliability: IGBTs are essential parts of many power electronics systems, and they can malfunction and cause expensive downtime as well as damage to the equipment. IGBT testing can assist in spotting possible issues early on and averting disastrous failures.

- Evaluating device performance: IGBTs are intricate devices with a range of performance attributes, including thermal performance, efficiency, and switching speed. Verifying that IGBTs are meeting the application's performance requirements can be aided by testing them.

- Optimizing device design: IGBT testing can assist in identifying areas where device design can be enhanced to increase cost-effectiveness, performance, or reliability.

Parameters to Evaluate During IGBT Testing

- Voltage: Testing for voltage ensures that IGBTs can sustain the prescribed voltage levels without malfunctioning.

- Current: Testing current ensures that the IGBT can manage the necessary current without failing or overheating.

- Temperature: The effectiveness of the IGBT's heat dissipation is evaluated through temperature testing.

- Switching Speed: This test assesses how fast the IGBT can transition between the on and off states.

Video related to How To Test an IGBT

Methods for Testing IGBTs

Non-Destructive Testing Methods

Non-destructive testing methods allow for the evaluation of IGBTs without damaging them. These methods are often used for initial testing or pre-shipment inspection:- Electrical Testing: This type of testing analyzes a range of electrical characteristics, including on- and off-resistance as well as threshold voltage. These measurements shed light on how well the IGBT regulates current flow.

- Thermal Testing: This method assesses how well the IGBT dissipates heat in different operating environments. A specific thermal chamber or a heat gun can be used for this.

- Diode Testing: Diode testing verifies that the internal diode of the IGBT, which guards against reverse voltage spikes, is still operational.

- Visual Inspection: Visual inspection entails attentively scrutinizing the surface of the IGBT to look for any damage indicators, discolorations, or cracks. This can assist in locating possible flaws in the manufacturing process or outside damage.

Destructive Testing Methods

Destructive testing methods involve physically damaging the IGBT to obtain more detailed information about its internal structure and performance:- Breakdown Testing: This technique establishes the highest voltage or current that an IGBT is capable of handling before failing. This sheds light on how durable the gadget is in harsh environments.

- Switching Speed Testing: Switching speed testing calculates how long it takes an IGBT to switch between the on and off states. This data is essential for applications that need quick switching.

- Gate Drive Testing: This test assesses the effectiveness of the gate driver circuit, which regulates the gate voltage, in the IGBT. By doing this, it is ensured that the IGBT is getting the right signals to function as intended.

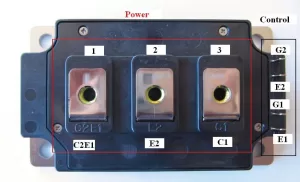

- Module-Level Testing: Module-level testing assesses the overall performance of an IGBT module, which is made up of several IGBTs and related circuitry. Ensuring the dependability of large-scale IGBT power systems is crucial.

Advanced Testing Techniques

Advanced testing techniques provide more comprehensive evaluations of IGBT performance:- Dynamic Characterization: This technique assesses how well the IGBT performs under varied load and temperature profiles by simulating real-world working conditions.

- Gate Driver Testing: This test evaluates the IGBT's gate driver circuit's performance, focusing on its capacity to manage switching transients and produce the proper gate voltage waveform.

- Module-Level Testing: Module-level testing assesses the overall performance of an IGBT module, which is made up of several IGBTs and related circuitry. This guarantees large-scale IGBT power systems' dependability.

What can cause an IGBT to fail?

- Overvoltage: Going above the IGBT's maximum voltage rating can result in premature failure and irreparable damage.

- Overcurrent: Going over the maximum current rating might result in component destruction, arcing, and overheating.

- Overheating: If the IGBT is used at a temperature that is too high, it may degrade more quickly and eventually fail.

- Short Circuits: A short circuit between the terminals of an IGBT can result in a fast current flow, which could harm the equipment.

- Manufacturing Defects: The IGBT's production process can include flaws that result in components that are weak or defective, which raises the possibility of failure.

Preventive Measures and Best Practices

To minimize the risk of IGBT failure, it is important to implement preventive measures and best practices:- Proper Design: IGBTs ought to be built with sufficient heat-dissipation capacity and the ability to endure anticipated operating conditions.

- Quality Control: To reduce the possibility of defects, strictly enforce quality control procedures throughout IGBT manufacture.

- Regular Maintenance: Arrange for routine maintenance inspections to spot possible problems early and stop disastrous breakdowns.

- Datalogging: Make use of data logging technologies to keep an eye on IGBT operating parameters and spot any patterns that might point to an imminent failure.

Where are IGBTs used?

IGBTs have found widespread applications in various industries:- Motor Drives: Electric motor speed and torque are managed using IGBTs.

- Power Inverters: To convert DC power to AC power, IGBTs are used.

- Switching electricity Supplies: IGBTs are utilized in a variety of electronic devices to control and transform electricity.

- Induction Heating Systems: IGBTs provide heat for a range of manufacturing and industrial operations.

Conclusion

In conclusion, testing IGBTs is essential to guarantee their longevity, dependability, and performance. Engineers and technicians can detect possible problems, verify the IGBT's specs, and decide how best to use them by using the right testing strategies and procedures. Preventive maintenance and routine testing can greatly extend the life and effectiveness of IGBT-based systems. It is becoming more and more crucial to comprehend IGBT testing standards as they continue to grow in popularity across a variety of industries.Populer Posts

1SG280HN1F43E2LGS3

Intel

1SG110HN1F43E2LG

Intel

5SGXEA4K1F35C2G

Intel

M2GL005-FGG484I

Microchip Technology

M1AGL250V5-VQ100

Microchip Technology

10AX048E2F29I2LG

Intel

XC4025E-3HQ240I

AMD

M2GL010-VFG400I

Microchip Technology

LCMXO3L-9400E-6MG256C

Lattice Semiconductor Corporation

ATT2C123S208-DB

Lucent