Comparison of PLC and Arduino: What’s the difference?

September 12 2023  1826

1826

Inquiry

Global electronic component supplier AMPHEO PTY LTD: Rich inventory for one-stop shopping. Inquire easily, and receive fast, customized solutions and quotes.

QUICK RFQ

ADD TO RFQ LIST

PLCs and Arduinos are two examples of electronic control devices that can be used to automate processes. The ideal option for a given project will rely on the exact requirements as they each have various strengths and drawbacks. In this blog, we will discuss the key differences between PLCs and Arduinos, and help you decide which device is right for you.

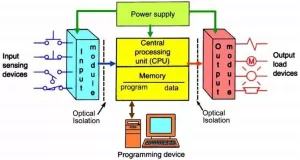

What is a PLC?

A Programmable Logic Controller (PLC) is an industrial computer with different inputs and outputs that uses custom programming to control and monitor industrial equipment. Manufacturing, the food and beverage industry, as well as the water and wastewater treatment industry, all employ PLCs.

PLC Components

- Central processing unit (CPU): The CPU runs the control program and serves as the PLC's brain. It is an electronic device with a processor, memory, and I/O ports.

- Input/output (I/O) modules: The PLC is linked to the process using I/O modules. They could be digital or analog modules. Analog modules take measurements of physical quantities and transform them into electrical signals, such as the level of a liquid. A switch or sensor's status is measured by digital modules, which then transform it into a binary signal.

- Memory: The memory houses the control program as well as other information, such the input and output statuses. Depending on the kind, the memory may be either volatile (which loses its contents when the power is switched off) or non-volatile (which keeps its contents even when the power is turned off).

- Power supply: The power supply powers both the I/O modules and the PLC controller. It transforms mains AC electricity into DC power that the PLC may utilise.

- Programming tool: The PLC controller is programmed using the programming tool. It might be a programming terminal, a laptop computer, or a portable programmer.

- HMI (human-machine interface): The PLC controller can be contacted using the HMI. It could be a light bar, a keypad, or a touchscreen display.

- Communication modules: The PLC controller is linked to other devices using communication modules, including computers and networks. This makes it possible to remotely program, monitor, and control the PLC controller.

What is an Arduino?

An Arduino is an open-source platform that aids in the creation of electronic projects by circuit designers. It is made up of hardware and software. Microcontrollers, which are programmable circuit boards, make up the Arduino hardware. Developers write and upload code to the microcontroller using the Arduino software, which is an IDE (integrated development environment).

Arduino Components

- Microcontroller: The Arduino board's microcontroller is its brain. The Arduino software is run on a little computer via this device.

- I/O (input/output) pins: The I/O pins are used to attach the Arduino board to external devices. They are able to read data from sensors or manage output devices like motors or LEDs.

- Power source: The Arduino board receives power from the power source. It can be an external power source or a USB cable.

- Language for programming: A condensed version of C/C++ is used in the Arduino programming language. Beginners should choose it because it is simple to use and learn.

- Development environment: Arduino programs are written and uploaded using a software tool called the Arduino development environment. It may be used with Windows, macOS, and Linux.

- Libraries: Arduino libraries are collections of code that make it easier to create programs for the platform. For a range of functions, like reading sensor data, managing motors, and connecting to the internet, there are libraries available.

Video related to PLC vs Arduino

How does a PLC system work?

The PLC gathers data from attached sensors or input devices, processes it, and then initiates outputs in accordance with pre-programmed specifications. A PLC can monitor and record run-time data, such as machine productivity or operating temperature, depending on the inputs and outputs. It may also automatically start and stop processes, create alarms in the event of a machine malfunction, and do other tasks. A versatile and reliable control solution, programmable logic controllers can be applied to practically any application.

How does an Arduino work?

- Connect your PC to the Arduino board. A USB cord is useful for this.

- Install the software for Arduino. There are Windows, macOS, and Linux versions of the Arduino software.

- Launch a fresh drawing. An Arduino sketch is a program.

- Program your computer. Your program can be written in the Arduino programming language.

- Your software will be uploaded to the Arduino board. Utilizing the Arduino software, you can achieve this.

- Check out your program. You can test your software by attaching sensors and output devices after you've uploaded it to the Arduino board.

Comparison of PLCs and Arduinos

The following table compares PLCs and Arduinos in terms of a number of key factors:| Factor | PLC | Arduino |

| Cost | More expensive | Less expensive |

| Complexity | More complex | Less complex |

| Programming language | Ladder logic, FBD, Structured Text | C, C++, Python |

| Community | Smaller community | Larger community |

| Applications | Industrial automation, process control | Hobby projects, education, research |

What is the difference between PLC and HMI?

Human-machine interface is referred to as HMI. User interaction with a PLC or other industrial control system is made possible by a graphical user interface (GUI). In most cases, HMIs show real-time data from the system, including sensor readings and process status, and let users adjust the system's parameters. Here is a table summarizing the key differences between PLCs and HMIs:| Feature | PLC | HMI |

| Purpose | Control industrial processes | Provide a user interface for interacting with a PLC |

| Hardware | Standalone device with processor unit, input/output modules, and communication interfaces | Computer with graphical user interface |

| Programming language | Ladder logic, structured text, function block diagram | Graphical programming languages, such as InTouch, Wonderware, and FactoryTalk |

| Complexity | Complex, requiring specialized knowledge to program | Less complex, can be programmed by non-technical users |

| Cost | More expensive | Less expensive |

Arduino vs Raspberry Pi

Raspberry Pi is a single-board computer. This indicates that it is a more effective tool that may be utilized for a variety of jobs. To run web servers, play games, or even create full-fledged apps, Raspberry Pi boards can be used. Because they can be used to operate motors, sensors, and cameras, they are also a popular option for robotics projects. Here is a table summarizing the key differences between Arduino and Raspberry Pi:| Feature | Arduino | Raspberry Pi |

| Purpose | Control electronic devices | Run software applications |

| Hardware | Microcontroller | Single-board computer |

| Processing power | 8-bit | 64-bit |

| RAM | 2 kB | 1 GB |

| Operating system | None | Linux |

| Programming language | C/C++ | Python, Java, C/C++ |

| Cost | $20-$50 | $35-$100 |

What is a PLC used for?

- Machine control: PLCs are used to control the functioning of machinery, including packing equipment, robots, and assembly lines. A PLC could be used, for instance, to regulate an assembly line's workflow or the speed of a conveyor belt.

- Process control: PLCs are used for process control to regulate the flow of materials like liquids, gases, and powders. For instance, a PLC might be used to regulate the pressure in a hydraulic system or the temperature of a chemical reactor.

- Safety control: PLCs are used to manage safety-critical systems, such as those that stop equipment from running in a dangerous manner. For instance, if a door is opened while a machine is running, a PLC could be used to shut it off.

- Data collection: By using PLCs, data from sensors may be gathered and sent to a computer for processing. For instance, a PLC could be used in a process control system to gather information on the temperature, pressure, and flow rate of a liquid.

- Communication: PLCs have the ability to interface with various devices, including computers, HMIs, and other PLCs. A PLC could be used, for instance, to accept instructions from a human operator or to convey data from a sensor to a computer for analysis.

What is an Arduino used for?

- Home automation: You can use an Arduino to automate your home's lights, appliances, and other fixtures. Arduino, for instance, can be used to build a smart thermostat that modifies the temperature in accordance with your schedule or the weather.

- Robotics: Arduino is a well-liked option for robotics projects. It may be used to manage various sizes and types of robots. Arduino, for instance, can be used to build a robot that can pick up things or navigate a maze.

- Internet of Things (IoT): Arduino can be used to build online-connected IoT gadgets. For instance, you could use Arduino to build a sensor that records your home's temperature and uploads the information to the cloud.

- Education: Arduino is a well-liked educational tool for teaching programming and electronics. There are many resources available to assist you in getting started, and it is comparatively simple to understand and use.

- Art and design: Interactive art and design projects can be made with Arduino. For instance, you could use Arduino to build a wearable device that tracks your motions or a light sculpture that responds to music.

Is Arduino similar to Raspberry Pi?

Although both Arduino and Raspberry Pi are open-source electronics platforms, they each offer unique advantages and disadvantages. Because it is simpler to use and has a larger selection of development tools accessible, Arduino is more well-liked among beginners. Although Raspberry Pi is more capable and may be used for intricate projects, it is also more challenging to understand.Advantages and disadvantages of PLC and Arduino

Advantages of PLC

- Several different control applications

- The paperwork was simple to complete.

- Programming security that is flexible enough to accommodate production changes

- PLC has many contacts, is inexpensive, and is secure.

- Programming and reprogramming problems solving

- The controller already has input and output interfaces

- One programmable logic controller may easily control numerous machines, making it adaptable.

- PLCs can be easily programmed using a relatively simple programming language.

Disadvantages of PLC

- When power is restored, some PLCs start up, which could result in an accident.

- It is difficult to make modifications or replace things.

- Need more security measures, such as

- Some applications that carry out a single task are inefficient while using PLC.

- Restricted environments Vibrations and high temperatures can damage electronic components on the PLC.

- PLC is created by semiconductors, and it is based on the thermal properties.

- A difficulty develops when PLC is used; the hold up time is indeterminate and typically long.

Advantages of Arduino

- Cheap: Arduino boards are reasonably priced. If you're skilled, you could even create an Arduino module by yourself or buy one that has already been put together for less than $50.

- Flexible enclosure design: A bare integrated circuit board serves as the foundation of an Arduino system. Flexible enclosure design. Almost every part of the equipment or process being controlled can have it mounted directly to it. The housing or case of the Arduino controller may be specially made, or it may be made from the object being controlled.

- Small and Compact Size: Due to their extremely low space requirements, Arduino devices can be put in practically any available space. The no-case design also shows improved heat dissipation.

- Open architecture: It makes use of Integrated Development Environment (IDE) design, in which programming tools and facilities—specifically, the code builder, test, and debugging tool—are bundled in a single interface.

- Extremely mobile and portable: Arduino-based devices may attain the highest levels of mobility and portability thanks to their extremely tiny form factor and programmable enclosure. Miniature robots that can travel from one place to another are an excellent illustration of this characteristic. These robots have sleek, compact bodies and can maneuver in small places. These robots are primarily Arduino-based.

- Common accessories and connectivity tools: Typical household products are accessories. Some of these parts include cables for communication and power. There are manufactured, ready-to-use accessories available, but these household items will undoubtedly be useful when creativity and customisation are required.

Disadvantages of Arduino

- Memory: The amount of memory on the Arduino board is insufficient to store programs and variables. It cannot be upgraded with external RAM either. External memory can be used with the ATmega32 and ATmega128 but their I/O functionalities cannot be used.

- Speed: The Arduino CPU clock rate ranges from 8 to 20 MHz, which is significantly lower than that of most platforms. Each clock cycle allows for the execution of many instructions, which means there is a substantial amount of CPU activity to be managed in the time between each pulse.

- Electrical power: You must take voltage settings into account while dealing with Arduino hardware because certain components have 3.3V I/O while others are 5V tolerant. You could damage your Arduino if you connect a 5V transistor-transistor logic circuit to a 3.3V device since it would affect the hardware.

Conclusion

Both PLCs and Arduinos are capable devices that can be used to automate processes. The ideal option for a given project will rely on its particular requirements. Arduino is an excellent option if you're seeking for a gadget with a variety of programming tools that is also simple to use. A PLC is a superior option if you're seeking for a tool that is more potent and can be used for projects that are more complicated.Populer Posts

ATT2C082S240-DB

Lucent

5SGXEA4H3F35C2G

Intel

EP4SGX230HF35C2N

Intel

AFS600-FGG256I

Microchip Technology

5SGSMD5H2F35I3LG

Intel

EP4SE820H40I4N

Intel

XC3130-4TQ100C

AMD

LCMXO1200C-5TN144C

Lattice Semiconductor Corporation

1SG085HN2F43E2LG

Intel

1SG110HN1F43E2VG

Intel